A new aquafeed made from insect protein for the aquaculture sector

An EIT Food funded project transformed organic waste streams into, a valuable, next generation sustainable aquaculture feed ingredient called METAFEED Alpha.

What will you learn?

In this case study you will learn about:

- The challenges with conventional aquafeed ingredients

- Why insect meal is a good alternative

- Details about a new product launched from an EIT Food supported project

Many fish farmers want to contribute to more sustainable aquaculture production, yet the aquafeed they use to feed their fish is usually based on unsustainable feed ingredients. We introduce a new aquafeed that is sustainably produced using insect protein.

The Challenge - conventional aquafeed ingredients are often scarce, environmentally damaging and expensive

More than half of the fish consumed globally come from aquaculture, a supply that is predicted to rise to 62% by 2030 and is further projected to provide most of the aquatic-derived proteins in people’s diets by 2050 (1).

Aquaculture is the fastest growing food sector. However, further growth can only be achieved sustainably if the supply of the commonly used protein rich raw ingredients in aquafeeds, such as fishmeal or soyabean meal, are replaced with sustainable options (2).

In addition to these aquafeed sources being mostly imported from outside of Europe and becoming increasingly more expensive, they also can have detrimental consequences on the environment. For example, fishmeal is mainly derived from the capture of wild fish, including small “forage” fish, which are at overcapacity. Also, soya bean meal production is linked with deforestation, a major land use change resulting in greenhouse gas (GHG) emissions. Unfortunately, these unsustainable fish feed ingredients are often the only available option for fish farmers.

Learn more about why alternative and sustainable commercial fish feeds are needed here

The Solution – Insect meal provides a sustainable alternative

Insect meal, produced from Black Soldier Fly (Hermetia illucens or BSF) larvae, is recognised as an under-utilised resource that has an excellent nutritional profile and can provide a sustainable solution as a promising functional protein alternative in fish feed. It offers a unique opportunity to address perceived challenges and mitigate the environmental impact in obtaining aquafeed from conventional protein sources.

Insect-based aquafeeds could help fish farmers to improve the sustainability of their operations, by providing their fish stocks with a sustainable alternative to conventional feeds.

Using Black soldier fly as a sustainable aquafeed source

Black solder fly (BSF) larva are a fast growing, non-disease, non-pest species that are compliant with EU regulations as a source of animal protein i.e., insect meal for use in fish feed (3). They do not compete with human food sources, unlike other feed protein sources such as soybean.

The main species of fish farmed in Europe such as Atlantic salmon, rainbow trout, or the common carp, are carnivorous or omnivorous, which means that protein is an essential requirement in their diet. The insect meal is naturally derived source of nutrition and serves as a functional feed with ingredients that have a positive effect on fish health. Its nutritional profile is as follows:

- Insects such as BSF contain up to 50% of high-quality protein as well as essential vitamins, fats, and amino acids.

- They are also rich in antimicrobial, medium-chain fatty acids, which have proven gut health benefits.

Approaches to producing a new, sustainable aquafeed

An EIT Food funded project called Metamorphosis, harnessed the power of insect bioconversion, which is the process of converting food waste into animal feed via insects, followed by bioprocessing and fermentation technologies, to generate different formulations of Functional Insect Meal (FIM) as a protein rich diet for adult Atlantic Salmon.

The safety and performance of the resulting formulations was then examined and measured using a variety of tests in the laboratory, followed by field trials.

BSF larvae were grown at scale, using the following process:

- Low value food waste i.e., shredded potatoes and spent brewers’ grain was treated using a proprietary process enabling it to be upcycled into larvae feed.

- The BSF seed stock were then grown on the larvae feed in an automated process using artificial intelligence to monitor feeding and growth for up to 14 days.

- The larvae were harvested and then fermentation and bioprocessing were used to create the Functional Insect Meal.

Converting Black soldier fly into Insect Meal – how the process works

METAMORPHOSIS, a novel state-of-the-art bioprocessing platform created by Better Origin incorporates microbial fermentation technology that was used to boost the nutritional and functional benefits of the BSF-derived feeds. This fermentation platform introduces specific bacteria that modify the composition of the insect larvae substrate, in particular they breakdown the abundant biopolymer chitin i.e., de-chitination, to improve digestibility and bring nutritional and health benefits.

Project Results: functional insect meal for salmon

Excellent performance indicated the potential go-ahead for inclusion of novel functional insect meal (FIM) as a sustainable salmon feed-ingredient.

Notably, FIM ingredients were assessed in terms of fish growth, safety and health benefits. It was shown that FIM could successfully replace up to 10% of Soy Protein Concentrate in the diet of juvenile salmon. Higher inclusion levels and adult salmon diets will now be tested.

Project outcome and future: a new aquafeed

A new product called METAFEED Alpha resulted from the EIT Food funded project. As a next step, partners in the feed chain have been identified to aid delivery of the new product to the market.

Also, the technology developed during this project is now being scaled to commercial volumes with the help of private investment and UK Government funding. By scaling the technology, it is hoped that it will be used on a large commercial scale in the future, to enable large scale production of sustainable aquafeed for the aquaculture industry (4,5).

In the future, fish farmers will be able to feed their stocks using a sustainable insect-based feed and be reassured that the feed is less harmful to the environment compared to unsustainable conventional options.

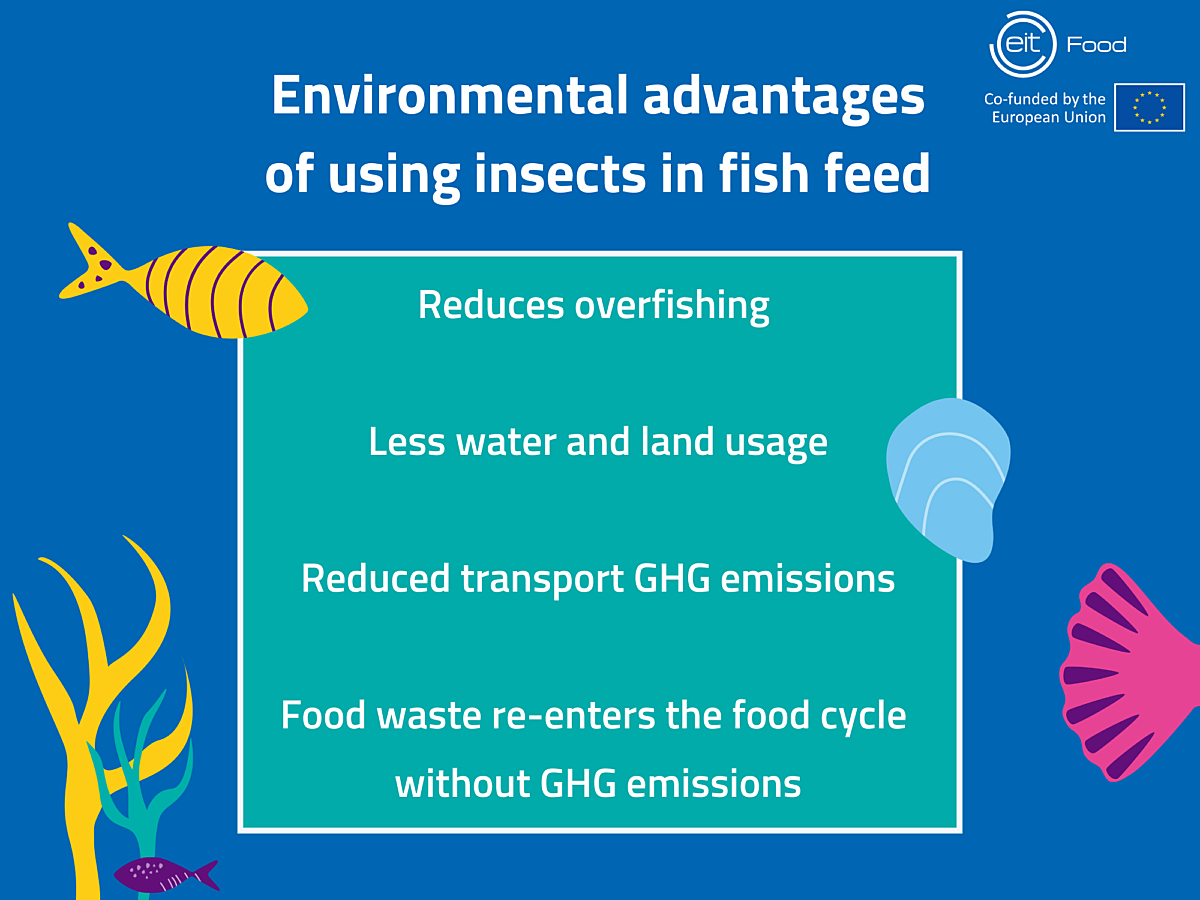

Environmental advantages of using insects in fish feed:

Many fish famers want to provide their fish stocks with more sustainable aquafeed to help towards environmentally friendly production. Advantages of using insects in aquafeed include:

- The BSF bioconversion approach contributes to the circular economy and enables food waste to re-enter the food cycle without greenhouse gas emissions.

- Insect protein produced locally would reduce the GHG emissions associated with transport of ingredients such as soya or fishmeal from abroad.

- Insects need far less water and land than conventional feeds like soy.

- Insects farmed locally mitigate destruction of important habitats for cultivation of soy and reduce overfishing.

- Provides a more economical solution that can also contribute to a new industry with potential high market and societal impact as new jobs are created, and current waste streams can also be utilised as part of the process.

- Improved health and welfare: From affecting the gut’s microbiome and trying to preserve a healthier bacterial community there, to training immune systems to make livestock more resistant to disease challenges and at the same time reduce the need for veterinary medicines, antibiotics, and vaccines.

About the project consortium – a powerful combination of complementary knowledge, skills and capabilities

Matis (Iceland)

Matis has long experience in developing and evaluating novel raw materials for feed and food, nutrient analyses and in vivo testing in high-throughput fish trials, conducted at its state-of-the-art National Reference Laboratory (NRL) and aquaculture facilities. Matis produced Functional insect meal (FIM) feed.

CSIC (Spanish National Research Institute)

IATA-CSIC expertise in food fermentation, preservation procedures and microbiological analysis. Used their knowledge of EU food & feed regulation, to assist in building a regulatory compliance case for the novel technology product.

Entomics Biosystems/BETTER ORIGIN

Trading as Better Origin, Entomics led the production of functional insect meals through their patented METAMORPHOSIS bioprocessing platform and worked towards verifying a compliant and safe product for use in aquaculture.

References

- FAO: Global aquaculture outlook in the next decades: An analysis of national aquaculture production forecasts to 2030

- Science Direct: Evaluation of Bacillus pumillus SE5 fermented soybean meal as a fish meal replacer in spotted seabass (Lateolabrax maculatus) feed

- Official Journal of the European Union: July 2017 in EU Regulation 2017/893

- The Guardian: UK insect farm project for sustainable animal feed awarded £10m

- Better origin: Better Origin secures government funding to scale up insect farming

More News from EIT Food West