Just Add Water

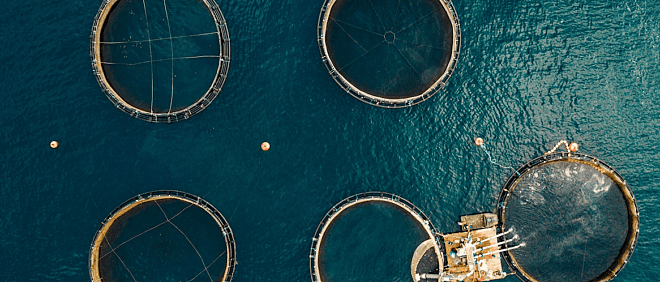

FishFrom Ltd will grow Atlantic Salmon from egg to 5kg in land-based Recirculating Aquaculture Systems (RAS), and thanks to EIT Food funding and in partnership with the Universities of Trento and Bologna and The Innovation Hub of Trentino (HIT), FishFrom Ltd will commercialise a technology that improves animal welfare and product quality.

FishFrom Ltd will grow Atlantic Salmon from egg to 5kg in land-based Recirculating Aquaculture Systems (RAS), and thanks to EIT Food funding and in partnership with the Universities of Trento and Bologna and The Innovation Hub of Trentino (HIT), FishFrom Ltd will commercialise a technology that improves animal welfare and product quality.

Fish grown in RAS can have a “muddy” taste caused by a build-up of certain bacteria in the water that are absorbed by the fish. Currently, removing these bacteria from the fish requires 12 days of depuration treatment. This is costly in terms of equipment and energy requirement, whilst negatively impacting on fish welfare. The technology to be further developed, trialled, and then commercialised by the team will eradicate these bacteria. It will also reduce energy consumption, fish weight loss and stress. This will give the consumers a tasty and healthy product that has been sustainably grown in the best farming conditions, with minimal environmental impact. The USP’s are:

PREDICTABLE QUALITY: The fish will be of the highest quality, and supplied fresh to customers every week without vaccines or antibiotics use.

ANIMAL WELFARE: Farmed in highly oxygenated, temperature controlled, pristine water, ensuring healthy fish, free from pathogens and parasites

CIRCULAR ECONOMY: Recycling 98% of all water, using sustainable feed ingredients, with waste products captured, reused, and valorised. Farmed close to market, reducing food miles and packaging. The salmon market is mature within Europe and the EU. Salmon is traded as a commodity but a sustainable brand with a strong USP, or country of origin like Scotland, can command a higher price/kg. Our team having worked within the traditional salmon farming industry for many years assess the main customer complaints as:

- Missed delivery due to weather events preventing harvesting

- Inconsistent size and quality across the year due to multiple farm harvests and biological challenges in the sea (sea lice and pathogens affecting growth, yield and flesh quality)

- Non-conformance to accredited standards for production, quality, environmental impact and animal welfare.

The salmon grown in the FishFrom facility will live in a fully controlled recirculation environment that provides the optimal conditions for growth and well-being that is not affected by weather, pathogens or predators. The fish will be fed an optimal diet created from sustainable sources and specifically designed for the RAS environment. All waste products will be recovered and reused/recycled to create as market allows a small but important additional revenue stream. With this production methodology and the use of the Unitn Sys PO water treatment technology, we will produce salmon of a consistent quality that tastes fresh from the sea. When the fish reach market size, they will be humanely slaughtered in accordance with globally recognised welfare standards. Production will have the highest animal welfare, be sustainable and be ethical – this is what the discerning consumer wants and is willing to pay for.

The technology developed in the project can also be applied to other aquaculture species which will mean that better quality fish will be available more regularly to a larger section of the population and, with upscaling and competition, will become more affordable.

The consortium will improve efficiency in growing Atlantic salmon, from egg to harvest, on land and all under one roof while reducing cost of production and improving animal welfare.

To enable us to develop a 3,600 tonne RAS salmon farm, our approach will be modular and systematic.

Phase 1:

- Construction and installation of the Sterner RAS equipment into the facility

- Development of the first laboratory prototype filtration unit (10 m3) by the University of Trento

- Development by the University of the larger scale filtration unit (600 m3) and installation into the facility

Leading to,

Phase 2:

- Construct and install a 3,600 tonne RAS facility on the same site as Phase 1

- Create and install the commercial scale of the prototype filtration unit (30,000 m3)

The whole farming process is scalable and can be replicated in the UK and EU. The project is in an advanced state of readiness, with planning consents and licences granted.

The consortium can be expanded at stage 2, however it shows the essential competences needed to complete Phase 1. The University of Trento TN will mainly test photocatalytic ozonation to reach TRL6 or higher, to remove the off-flavour bacteria. FishFrom will deal with up scale up and explore all parts of the value chain with suppliers, customers, and regulators. This technology will be disruptive to the existing well established salmon aquaculture sector.

Project lead

Related Projects