Results

This page shows the results of Lab on a Chip - Early-warning platform for food safety.

Results 2021

Consumer Study

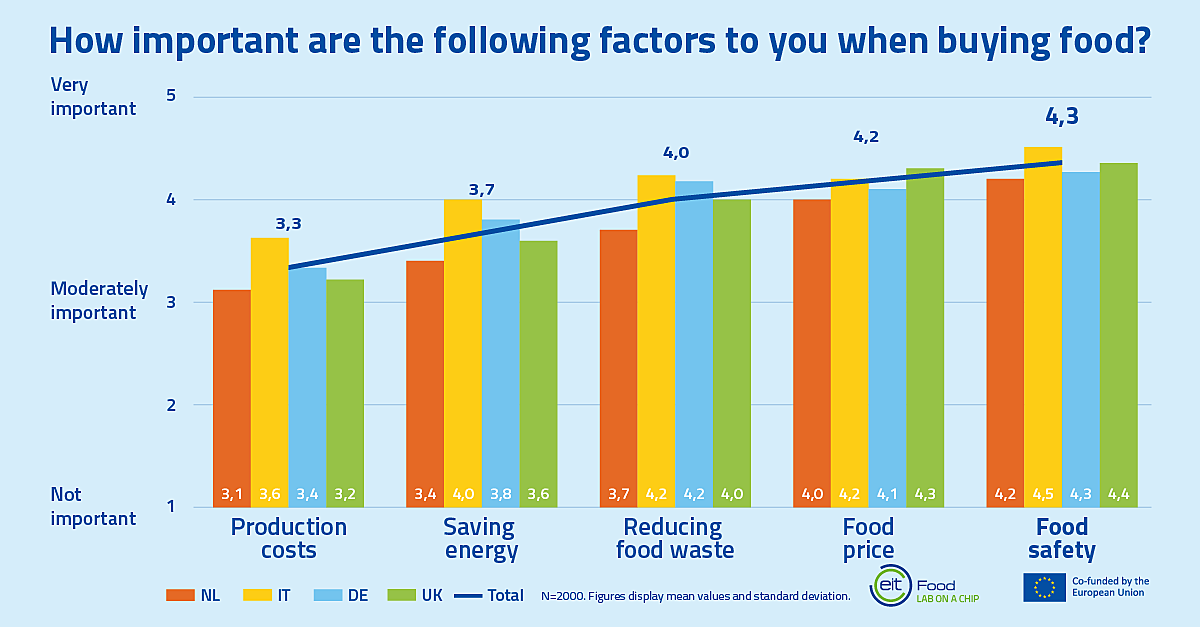

The aim of the study was to quantify consumer needs, attitudes, and perceptions concerning food safety and rapid detection devices for food contamination across countries. The study included 2,000 consumers (500 per country) across the UK, Germany, Italy, and the Netherlands.

KEY FINDINGS

Importance of factors affecting food purchase

Respondents were asked to rate the importance of food safety, food waste prevention, energy savings, food price and production costs when buying food, based on the potential benefits Lab on a Chip technology could have if adopted in the supply chain. The results showed that consumers tend to value food safety, food price and food waste higher than production costs and energy savings.

Food contaminant testing with the Lab on a Chip technology

After having received information about food contaminant testing and the Lab on a Chip technology, participants were asked about their attitudes towards the technology. The results showed that:

- Respondents from all countries agreed that food contaminant testing was of high importance.

- Respondents generally considered meat, fish, dairy, and eggs to be the most important to test with Lab on a Chip technology (from a list of 15 different food groups).

- Respondents prefer that producers conduct food safety testing rather than farmers or retailers.

- Respondents expect to pay less, or at least not more, for foods that have been tested with Lab on a Chip technology.

- The food label was the most preferred communication channel to know if the food has been tested with Lab on a Chip technology.

Attitudes towards the Lab on a Chip technology

When participants were asked about the importance of various benefits offered by this technology, the results showed that:

- Respondents consider food safety, followed by food waste prevention as the most important benefits.

- Respondents do not have a clear identification of the link between food technologies and their overall benefits.

- Most respondents had higher food safety concerns related to the COVID-19 pandemic, concerns that could be related, at least in part, to the person(s) handling the food, and where the food comes from.

CONCLUSIONS

- There is a market need for Lab on a Chip rapid detection technology, which would add value and help make products more attractive to the consumer.

- Respondents prioritize food safety and food contaminant testing and consider the benefits of Lab on a Chip technology important to them.

- Consumer awareness of food safety and handling is needed. Consumers prefer to be informed through the product label.

- Respondents are more concerned about the food safety and food waste prevention aspects of the technology than other benefits, so these aspects can be highlighted to consumers.

- Consumers do not expect to pay more for foods that have been tested with the technology.

- By identifying the food products that consumers are most concerned about, producers can be singled out as those that would benefit most from technology.

RESULTS 2020

Rapid and accurate bacterial count made possible by technological breakthrough

Recent work from the Lab on a Chip team has focused on a major part of worldwide microbiological testing, namely the bacterial detection of various types of cells called 'total count'. The objective of such tests is to obtain a preliminary indication of whether a product contains bacteria and at what concentration. In the food industry, the ISO4833-1 standard specifies that for detection of bacteria, plates should be incubated at 30°C for 72 hours.

However, our innovative technique reduces the time for results dramatically from days to a few hours. In contrast to waiting for days for colonies to form on a plate, our rapid approach combining molecular biology with microfluidics enables immediate enumeration of both gram-positive and gram-negative bacteria. It is the genetics expertise of professor Kashi and the microfluidics expertise of professor Yossifon that allowed this technological breakthrough, which enables a rapid and accurate enumeration of bacteria.

The Lab on a Chip technology shows promising results

In this publication by Park et al. (2020), the technology demonstrated an ability to efficiently preconcentrate different analytes and to successfully increase immunoassay sensitivity, which highlights its potential in immunoassays serving the clinical and food testing industries:

Feedback from industry indicates great market potential

Time to result for laboratory analysis is often a bottleneck for food industries as standard lab analysis may be time consuming and can take up to several days.

Receiving laboratory analysis after several days often means taking a risk about ingredient or product quality (authenticity or safety): having onsite portable rapid detection solution is viewed as a way to support constructive early decisions in the production and release process, that can help reduce the risks.

Feedback from industry respondents showed that they wanted to have results for analysis more rapidly, in order to act rapidly:

- At the farming stage, when the supply chain may be destabilized by crop threats, taking action at crop disease asymptomatic stage.

- At the entry of the production line, to check the quality of incoming material and orient material to the appropriate production line, or reject incoming material.

- At the wash step of production lines, to verify there is no left over from the previous production batch when lines are used to prepare different products.

- Before the product is released, diminish the risk for consumers and the risk of recall when the product has to be released and cannot be stored until lab results are delivered. Or to diminish the cost of storage, when the product can be stored prior to release.

- To monitor contamination of their production lines and act rapidly in case of acute contamination.

These respondents also saw the availability of rapid onsite tests as means to review the decision-making path in the production process and limit ingredient/product loss